In today’s rapidly evolving business landscape, industries across the board face unprecedented challenges in supply chain management. The post-pandemic world has highlighted the need for more dynamic, responsive, and intelligent supply chain solutions. While many companies have invested heavily in systems like SAP, WMS, and other logistics support applications, these traditional tools often struggle to keep pace with the real-time demands of modern supply chains. Enter AI agents: the potential game-changers in supply chain management.

The current state of supply chain management

Modern industries rely on intricate networks of interconnected systems to manage their increasingly complex supply chains. Enterprise resource planning (ERP) systems, warehouse management systems (WMS), and various logistics applications form the backbone of these operations. However, these systems often operate in silos, making it challenging to respond quickly to market fluctuations.

Many companies have turned to Robotic Process Automation (RPA) to bridge gaps and automate routine tasks. While RPA has its merits, it’s often limited to mechanical steps like data entry or file-based import/export operations. The real decision-making still falls to human analysts, who often rely on productivity tools like Google Sheets or Microsoft Excel to process data and make critical decisions.

This current setup, while functional, leaves much to be desired in terms of real-time responsiveness, scalability, and predictive capabilities.

How AI agents can transform supply chains

The integration of AI agents into supply chain management represents a paradigm shift in how businesses handle logistics, inventory, and distribution. By leveraging advanced algorithms, machine learning, and real-time data processing, AI agents offer unprecedented capabilities that can address longstanding challenges in the supply chain industry. These intelligent systems are poised to revolutionize operations, offering solutions that are more responsive, efficient, and adaptable than ever before. Let’s explore the key ways AI agents are transforming supply chains:

- Real-time, conversational processes: AI agents enable digital, conversational, and real-time processes, continuously monitoring and adjusting supply chain operations as needed. This constant vigilance and immediate response capability ensures that supply chains can adapt to changes and challenges as they arise, rather than reacting after the fact.

- Enhanced visibility and scalability: These agents provide full visibility into new business rules, even when applied ad-hoc, offering enhanced transparency in decision-making processes. Once effective patterns are identified, they can be quickly scaled across the entire product portfolio,a capability that is frequently cost-prohibitive with traditional systems. This scalability allows businesses to rapidly implement successful strategies across their entire operation.

- Advanced analytics and dynamic planning: By analyzing vast amounts of data, including historical trends, current market conditions, and external factors like weather patterns or social media sentiment, AI agents can provide accurate forecasts and determine optimal inventory levels. This comprehensive analysis enables dynamic planning that adapts to changing conditions, ensuring that supply chains remain responsive and efficient in the face of market fluctuations.

- Seamless integration: One of the most significant advantages of AI agents is their ability to provide these advanced capabilities without requiring major changes to existing line-of-business applications. This seamless integration minimizes disruption to current operations while maximizing the return on existing investments, making the adoption of AI technology more feasible and appealing for businesses.

The art of the possible: AI in action for food and beverage

To truly appreciate the transformative potential of AI in supply chain management, let’s delve into a practical example. Consider a large food and beverage company grappling with the complexities of inventory management, demand forecasting, and distribution in an industry known for its perishable goods and rapidly changing consumer preferences. The integration of AI agents into their supply chain could revolutionize their operations, addressing longstanding challenges and unlocking new efficiencies. Here’s a detailed look at how AI could transform various aspects of their business:

- Intelligent inventory management:

AI agents continuously monitor stock levels across all warehouses and stores, creating a real-time, comprehensive view of inventory. When the stock of a particular item runs low, the AI automatically triggers reorders, considering a multitude of factors such as lead times, demand forecasts, and even upcoming promotions. This intelligent system prevents stockouts during peak times, such as heatwaves or holidays, while also minimizing overstocking of perishable goods. - Precise demand forecasting:

By analyzing diverse data sources including historical sales data, social media trends, weather forecasts, and local events, AI predicts demand with unprecedented accuracy. This multi-faceted approach to forecasting allows the company to anticipate shifts in consumer behavior and adjust their supply chain accordingly, reducing waste and ensuring product availability. - Dynamic pricing and promotions:

AI adjusts pricing in real-time based on current inventory levels, competitor pricing, and demand forecasts. It can also suggest and implement promotional strategies to balance inventory across different products or locations. This dynamic approach to pricing and promotions helps maximize revenue while also managing inventory efficiently. - Proactive supplier management:

AI agents monitor supplier performance, predict potential disruptions based on various factors (e.g., geopolitical events, weather patterns), and even suggest alternative suppliers when needed. They can also optimize order quantities and timing to minimize costs while ensuring adequate supply. This proactive approach to supplier management helps prevent supply chain disruptions and ensures a steady flow of goods. - Efficient Logistics:

By considering real-time traffic data, weather conditions, and delivery schedules, AI optimizes routing and scheduling for deliveries. This not only reduces transportation costs but also improves on-time performance, enhancing customer satisfaction and reducing the risk of spoilage for perishable goods.

This reimagined supply chain leverages AI’s capabilities to create a more responsive, efficient, and adaptive system. It addresses the unique challenges of the food and beverage industry, such as managing perishable inventory and responding to rapid shifts in consumer demand, while setting a new standard for supply chain management that can be applied across various sectors.

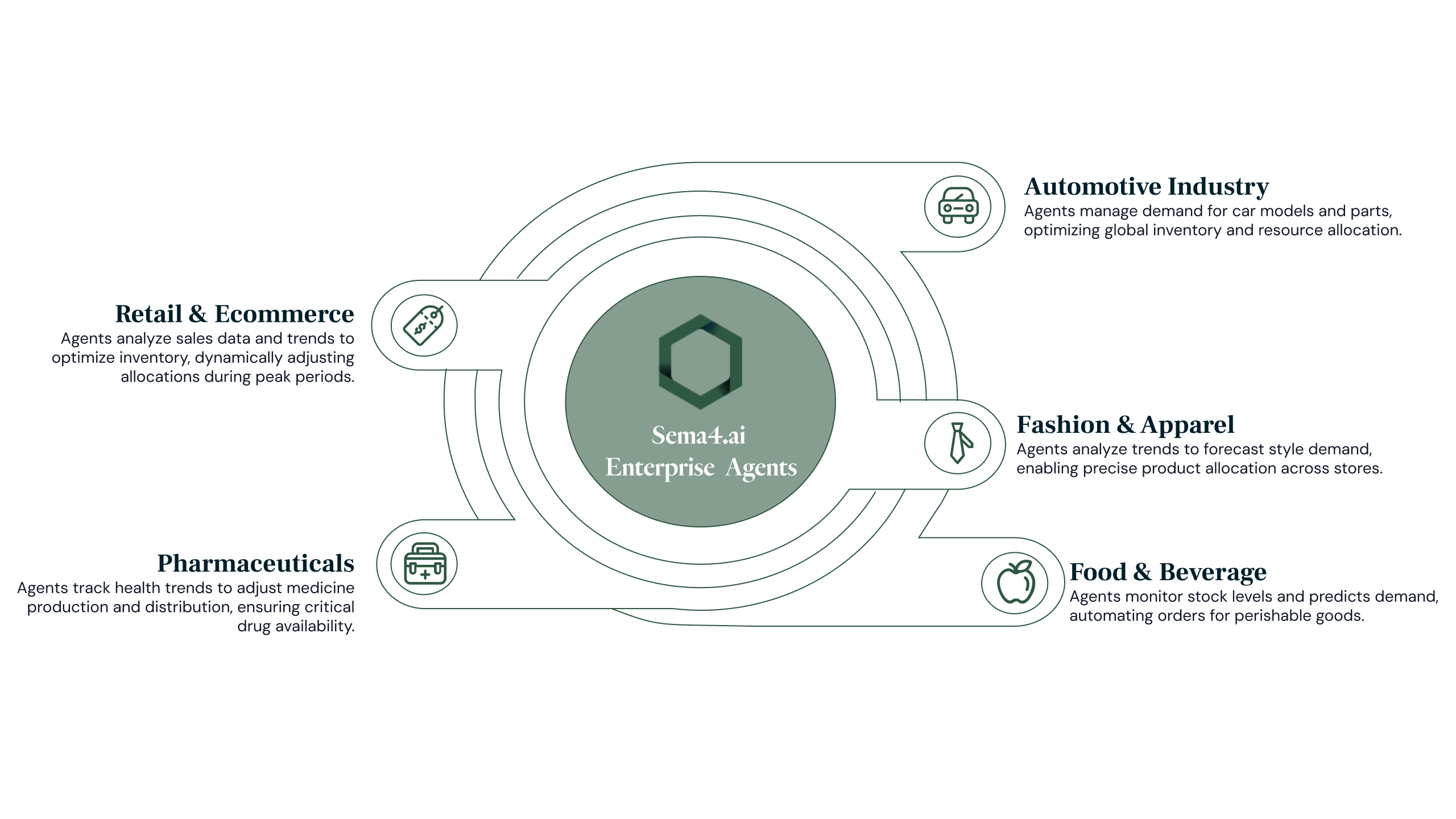

AI in supply chain across industries

The power of AI in supply chain management is not limited to a single sector; its ripple effects are being felt across diverse industries, each with its unique challenges and opportunities. From automotive manufacturing to pharmaceuticals, AI is revolutionizing how businesses manage their supply chains, offering solutions that were once thought impossible. As we explore the impact of AI across different sectors, we’ll see how this technology is not just optimizing existing processes, but fundamentally reimagining the very nature of supply chain management. Let’s embark on a journey through various industries to witness how AI is reshaping the landscape of global logistics, driving efficiency, and creating new paradigms of operation:

AI in the automotive industry supply chain

In the fast-paced world of automotive manufacturing, AI is the new engine driving efficiency. Major car manufacturers are harnessing AI to navigate their complex global networks. These intelligent systems anticipate market demands for specific models and parts, enabling just-in-time production and seamless distribution across international plants. By optimizing resource utilization and minimizing waste, AI is helping car makers stay ahead in an increasingly competitive market.

AI in fashion and apparel supply chains

The fashion industry, known for its rapid trends and seasonal shifts, is embracing AI as its new style guru. Fast-fashion retailers are using AI to keep pace with ever-changing consumer preferences. These smart systems analyze a myriad of data points – from social media buzz to weather patterns – to predict upcoming trends. This allows retailers to stay ahead of the curve, ensuring that the right styles reach the right stores at the right time, reducing waste and maximizing sales opportunities.

AI in pharmaceutical supply chains

The pharmaceutical industry is leveraging AI to ensure that the right medicines reach the right patients at the right time. AI systems in this sector are like digital epidemiologists, monitoring global health trends and predicting disease outbreaks. This foresight allows pharmaceutical companies to proactively adjust their production and distribution strategies, ensuring a steady supply of critical drugs where they’re needed most. In an industry where timing can be a matter of life and death, AI is proving to be a vital tool.

Retail and e-commerce supply chains

In the complex and dynamic world of retail and e-commerce, AI is emerging as a crucial tool for success. These intelligent systems are revolutionizing inventory management across thousands of products, analyzing a wealth of data including historical sales, seasonal trends, and social media sentiment to accurately predict demand. During high-stakes shopping events like Black Friday or Cyber Monday, AI shines by dynamically adjusting inventory in real-time, ensuring popular items are available to meet sudden spikes in demand. This agility not only boosts sales but also enhances customer satisfaction, turning potential stockouts into seamless shopping experiences. By optimizing stock levels and reducing overstock situations, AI is helping retailers stay competitive in an increasingly digital marketplace, balancing efficiency with customer expectations.

The future of supply chain management

As we look to the future, it’s clear that AI agents will play an increasingly central role in supply chain management. By enabling real-time, data-driven decision making, AI has the potential to create supply chains that are more efficient, more responsive, and more resilient than ever before.

For all companies looking to stay competitive in an ever-changing market, exploring the potential of AI in supply chain management isn’t just an option – it’s a necessity. The question is no longer “Can AI help?” but rather “How quickly can we harness the power of AI to transform our supply chain?”

Join our supply chain webinar

Secure your spot for our webinar: AI agents in action: Revolutionizing supply chain management

Build AI agents with Sema4.ai Studio

Build AI agents with Sema4.ai Studio

More AI agent resources

More Sema4.ai blogs & thought leadership

Build AI agents with Sema4.ai Studio

Want to get started? Join our Rapid Agent Deployment Program